PARTS YOURPROJECTS NEED

Having trouble locating obsolete, allocated or hard-to-find electronic components?You need it. We source it. Let us know what you’re looking for and we’ll find it.

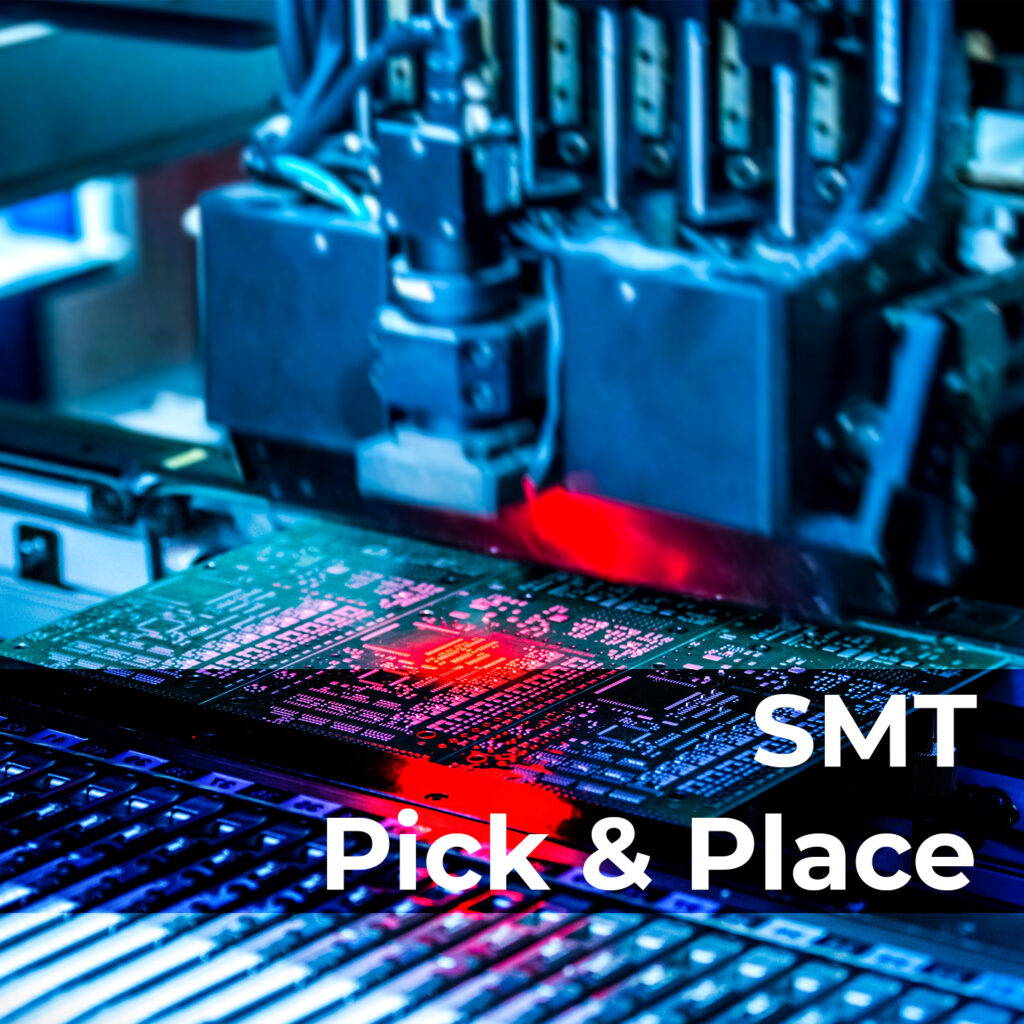

A pick and place machine, also known as a surface mount technology (SMT) machine or placement machine, is a crucial piece of equipment used in the manufacturing of printed circuit boards (PCBs). Its primary function is to precisely place electronic components onto the PCBs during the assembly process.

Here’s a brief overview of what a pick and place machine does:

The pick and place machine automates the process of picking up electronic components, such as resistors, capacitors, integrated circuits, and other surface-mount devices (SMDs), from their input sources (usually reels, trays, or tubes) and accurately placing them onto the designated locations on the PCB. This process is critical for creating a functional and reliable electronic circuit.

Pick and place machines are capable of high-speed and precise component placement, ensuring that the components are correctly positioned according to the PCB’s design and assembly instructions. They use vision systems, cameras, or lasers to identify fiducial marks or other alignment features on the PCB, allowing for accurate component placement.

These machines employ a combination of mechanical, pneumatic, and/or vacuum-based systems to handle and manipulate components during the assembly process. They use suction nozzles or grippers to pick up components from their input sources, hold them securely during transportation, and reComponent Handlinglease them at the designated locations on the PCB.

Some advanced pick and place machines are equipped with optical inspection systems that can verify the correct placement and orientation of components on the PCB. These systems can detect errors such as missing components, misplaced components, or components with incorrect polarity. Verification helps ensure the quality and accuracy of the assembled PCBs.

Pick and place machines are typically controlled by specialized software that allows operators to program the machine with the necessary component placement instructions. This programming includes specifying the coordinates, rotation, and orientation of each component on the PCB. The software also enables operators to optimize the component placement sequence for efficiency and to minimize production time.

Overall, pick and place machines are essential for automating the precise and efficient placement of electronic components onto PCBs during the manufacturing process. They significantly enhance the speed, accuracy, and productivity of PCB assembly, making them a critical component in modern electronics manufacturing facilities.